9 Year Old Micro-Channel Heat Pump Has Multiple Refrigerant Leaks in Johnson City, TN

May 3, 2025

Received a call from a new customer in Johnson City, TN stating that she needed a heat pump repair. She stated that her 9-year-old heat pump was not operating properly. She said that the indoor blower motor was moving air, but the outdoor unit was turning off and on. I advised her to turn the system off until I got there to help prevent any further damage to the system. If your heat pump isn't working, the best thing you can do as a homeowner, is to turn it off immediately. When I arrived, I took a look at the indoor unit to see what type of metering device the indoor unit utilized. I quickly realized that whoever had installed this piece of equipment did not install it up to code for where the home was located. There were no water safety devices on the unit and the condensate pump float switch was also not wired into the machine to help protect the homeowner’s property from water damage. I also noticed that the indoor unit used a micro-channel coil, which are prone to leaks especially if the installing contractor does not pull a deep vacuum on the system at install.

I went to the outdoor unit and noticed that it was a micro-channel coil as well. I also found more evidence that the local code was not followed when the unit was installed. The whips were not strapped to the home, the service disconnect was behind the unit and the unit wasn’t pulled 3 feet off the home, and the lineset wasn’t properly insulated with ¾” wall Armaflex insulation with a UV protectant coating applied to it. I hooked up my wireless probes to the system and found that the machine was almost dead flat on refrigerant. Heat pumps are sealed systems, so if you are low on refrigerant, it means that the system has a leak in it. The outdoor heat pump was going out on low pressure, which is why it was not cooling. Without refrigerant, the unit cannot cool or heat the home utilizing the heat pump.

I gave the customer our refrigerant leaks sheet to explain the 5 options that she had on her machine. The refrigerant leaks sheet gives the customer 5 different options on how to proceed from that point. Do nothing and have no heat pump operation, add refrigerant which would leak out quickly in her case due to her system being so low, attempt to repair the leak with a leak sealant which is not guaranteed to work and is a foreign substance in the machine, perform a leak search to locate the leak and then repair the system, or a system replacement. The customer decided to perform a leak search on the system so that she could know where it was leaking from.

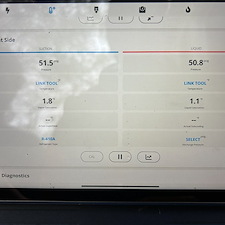

I recovered a tiny bit of refrigerant that was left in the system into a recovery cylinder making sure not to pull the system into a vacuum because I didn’t want to pull more moisture into the system than what may have already gotten into it with the refrigerant leak. Having a tiny bit of pressure just above zero leaves a little bit of trace gas in the system for leak searching it with a heated diode leak detector. I grabbed my digital gauges and a dry nitrogen bottle and pressurized the system to 357 psi. Within just a minute, the pressure had dropped 5 psi and was continuing to fall like a rock. Since, I was already outside I checked the outdoor unit with 2 of my heated diode leak detectors and followed up with my ultrasonic listening device and a micro leak detector bubble solution. I was unable to locate any leaks inside the outdoor unit. I reassembled the outdoor unit.

I went inside to the indoor unit and removed the doors and the panel off the coil so that I could leak search the coil fully from the inside and the outside. I immediately hit off in several locations on the indoor coil with one of my heated diode leak detectors. I followed up with another leak detector and rang off in the same spots. I sprayed some micro leak detector bubble solution on the indoor coil at the spots I alerted on with my heated diode leak detectors and could hear the leaks with my ultrasonic listening device. You could actually see the bubbles forming and running out into the indoor coil pan from the bottom of the indoor coil on each side. The customer had a leaking indoor coil in several locations which is why her unit was low on refrigerant.

I put the indoor unit back together. I left the outdoor service disconnect in the off position to prevent any further damage to the system by trying to run it while it was out of refrigerant. I let the customer know that I would get back in touch with her once I got pricing on a new indoor coil. I also advised her that just because we replace this indoor coil, she could develop a refrigerant leak in the outdoor micro-channel coil in the future. Being that her system was obviously installed with many shortcuts taken, I have no idea if proper installation procedures were followed by the previous contractor.

There is nothing more important to the longevity of your system than pulling a good deep vacuum on the system at installation. POE oil, which is in these systems today, has an affinity for moisture and if your contractor is not using a micron gauge while evacuating the system you can expect refrigerant related issues in the future. When I repair a system or install one I am using a micron gauge, I am using fresh vacuum oil on every evacuation, I am sweeping the system with dry nitrogen to move that moisture out, I am brazing while flowing nitrogen, I am using a properly sized liquid line filter drier, I am pressure testing with nitrogen to confirm system tightness, I am pulling a deep vacuum well below the manufacturer’s minimum specifications, and I am also performing a decay test upon completion of the evacuation process to confirm that we have a nice dry system free of moisture and contaminants.

The customer had bought the house with the heat pump already installed, so there was no parts warranty left on the equipment. I contacted the supply house who deals with this equipment and got pricing on a new indoor coil. I quoted the customer pricing on the repair and allowed her to make the best decision based on her needs and budget.

I am going to go on a bit of a tangent here regarding micro-channel coils. The one advantage of a micro-channel coil is that the machine requires less refrigerant in order to operate within its design parameters. Many manufacturers are moving to micro-channel coils because it lowers their investment in the machine during the manufacturing process by utilizing less refrigerant. Also, the manufacturers that utilize micro-channel coils advertise that they are helping the environment by using less refrigerant. Less refrigerant in a machine does save the customer a little bit of money on refrigerant related repairs, which is a nice benefit of having a micro-channel coil.

The disadvantages of a micro-channel coil are that they are more prone to refrigerant leaks, they clog up much quicker with debris during normal operation requiring more maintenance related costs to the homeowner, and when they do clog up with that debris, they take specialty cleaning solutions and much more labor to clear the coils than a traditional tube and fin setup, which costs the homeowner more in service-related costs. Not to mention, higher operating costs when they are clogged up and more wear and tear on the system as well.

It is kind of a catch 22 with micro-channel coils. They should be technically better for the environment because they hold less refrigerant, but if they leak more than a traditional coil, are they really better for the environment or are they just better for the manufacturers bottom-line? Less upfront costs in manufacturing and more service-related business in the future as they develop refrigerant leaks or clog up and cause further system damage. You will have to be the judge of that as a homeowner or purchaser of equipment that utilizes this technology. This is something that is a bit of a conundrum in the HVAC industry. With that being said, micro-channel coils have gotten a little more resilient over the years at not leaking refrigerant as manufacturers have fine-tuned their processes and they are becoming more mainstream in the industry across multiple manufacturers now.

If you are having issues with your HVAC system and are in need of a heat pump repair, please feel free to reach out to Magnolia Services based out of Johnson City, TN. We are not the pushy salesmen in white dress shirts and pressed pants arriving at your door trying to sell you a new system that you might not even need. We get our hands dirty, we investigate your system thoroughly, and we present the facts to you in a clear and concise manner so that you can make an informed decision. We stand by our motto, Quality Service You Can Trust. Stay safe and best wishes.

Location: Johnson City, TN

Project Image Gallery

Schedule Your HVAC Service in Johnson City, TN Today!

Or Fill Out Our Quick Form!