Broken Drain Line on a Heat Pump Flooding a Laundry Room in Johnson City, TN

May 23, 2025

Received a call from an existing customer in Johnson City, TN in need of a heat pump repair. He stated that he had water flooding his laundry room in the basement of his home and that the water appeared to be coming from his heat pump. We advised the customer to shut the heat pump off since it was dumping water onto the floor in order to prevent any further damage to the property.

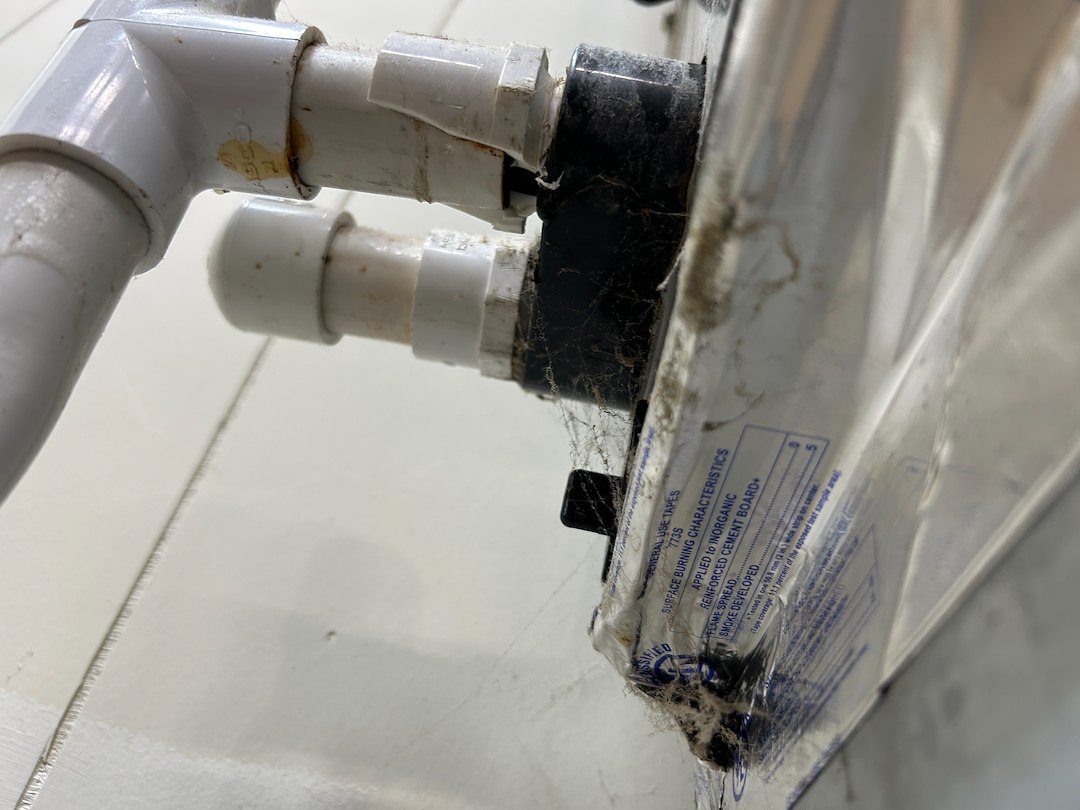

When we arrived the heat pump was still in the cooling mode because they did not want to go without cooling. We turned the thermostat off and pulled a metal sliding laundry basket out of the way that was sitting in front of the indoor air handler. We noticed that a 90 fitting on the right side was dripping water where the pipe had pulled loose. We also noticed a lot of water coming from the female slip to male threaded PVC fitting that entered the indoor coil pan. We looked under that fitting and noticed that it was broken and cracked apart.

We advised the customer of the situation and let them know that the drain line looked like it had taken an impact. We let them know that we could patch up what they had or run a new drain line for them with the correct pipe. Their drain line was thin wall PVC which is not nearly as strong and should not have been installed in the first place. Schedule 40 PVC should have been used, but the installing contractor chose to put in cheaper thin wall pipe to cut costs. The customer decided to just patch up what they had in order to keep their costs on the heat pump repair lower.

We removed the drain line from the unit and noticed that the p-trap was almost fully restricted with debris. We snaked the p-trap out and flushed it with water. We removed the broken PVC fitting that entered the indoor coil pan. We cleaned the threads of the pan. We applied a new PVC fitting with PTFE tape. We primed the fitting, the existing extension pipe on both sides, and the T-fitting. We applied PVC glue to those joints and bonded them together. We removed the pipe from the 90 on the right side of the drain that had come apart. We primed those connections and glued them together as well. We tested for leaks and we were good.

Since, we were already there we opened up the condensate pump and noticed lots of debris and slime inside the pump which can hurt the pump or clog the discharge line. We sucked out the water and slime from the pump and wiped it clean with a rag. We poured 1 gallon of foaming drain cleaner through the drain line cleanout and pan. Then, we ran multiple gallons of enzyme treated water down the drain as well. The foaming cleaner and enzyme treated water helps to further flush and clean the drain line, the condensate pump, and the discharge line of the condensate pump as well. Finally, we insulated the p-trap on the drain line to prevent nuisance sweating during cooling mode operation.

After putting the unit back together, we fired the unit back up in cooling operation and confirmed that we were putting out cold air. We sucked up the water from the floor with a shop vac and dried it with a towel. We offered to hook probes up to the refrigerant circuit for further testing since we were already there, but the customer declined and said that other than the water issue, the system had been doing well. If you are in need of a heat pump repair and live within our service area of Northeast Tennessee, please feel free to reach out to Magnolia Services based out of Johnson City, TN. Stay safe and best wishes.

Location: Johnson City, TN

Project Image Gallery

Schedule Your HVAC Service in Johnson City, TN Today!

Or Fill Out Our Quick Form!