Budget Friendly Heat Pump Repair in Kingsport, Tennessee Gets the Customer Cooling Again

August 1, 2025

We received a call from a new customer in Kingsport, Tennessee who was in need of a heat pump repair. He stated that the unit didn’t seem to be cooling very well during the hot days lately and then all of the sudden it didn’t seem to be cooling at all anymore.

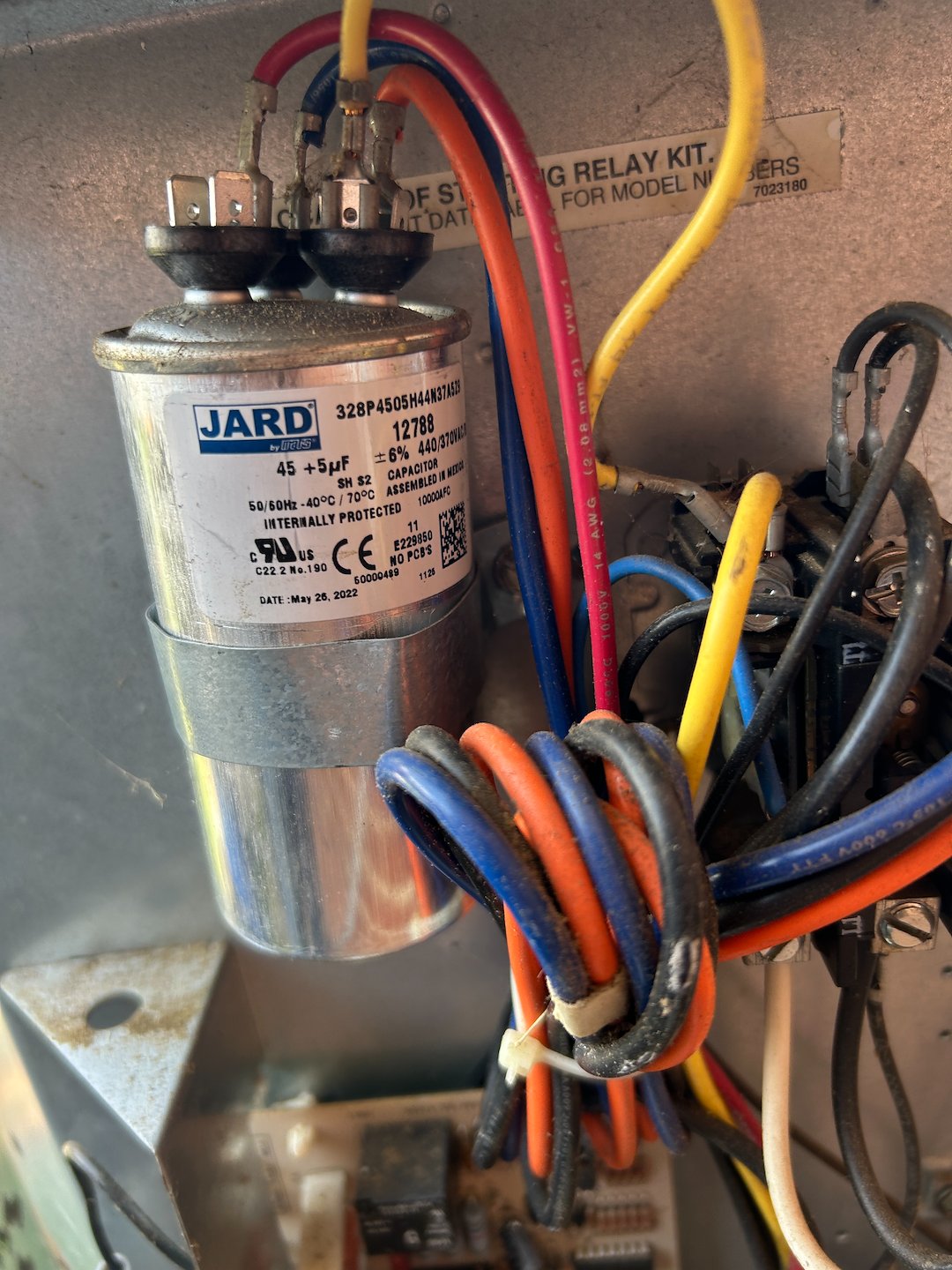

When we arrived, we took a quick look at the whole system. We opened up the outdoor unit and immediately noticed that the dual run capacitor was swollen like a frozen can left inside of a freezer. We tested the dual run capacitor and it was completely dead. We replaced the dual run capacitor with a quality USA made Mars capacitor. We fired up the system and it did start running both inside and outside. One problem was fixed.

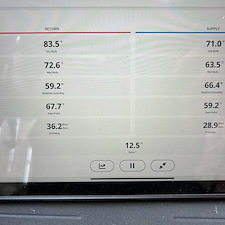

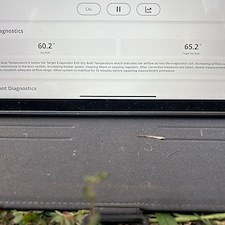

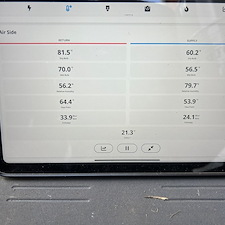

We noticed that the suction line was not getting cold and that the discharge air coming out of the heat pump was not very warm. We also had a poor temperature split between the return air and supply air. We received authorization to put our probes onto the system to analyze the refrigerant circuit. We verified that the indoor coil was using a thermostatic expansion valve (TXV) as the refrigerant metering device in cooling mode. We also documented that the HVAC unit did not have nearly enough return ductwork to adequately supply the indoor unit with the airflow it needed in order to operate within its design parameters. We also confirmed that the indoor blower was in high speed so there were no more airflow adjustments that we could make to the machine in order to move more air without enlarging the return ductwork. The unit was low on refrigerant which is why it hadn’t been able to keep up on those hot days before it quit working altogether.

We gave the customer our refrigerant leaks sheet that has 5 options on it so that he could make an informed decision based on the facts. We advised the customer that we should do a leak search and repair or replace the faulty component causing the machine to leak its refrigerant. The customer was on a tight budget and asked us to charge the machine up in order to get it cooling again even though this would only be a temporary fix. He did not have the budget for a leak search and repair at this time. If there is a leak inside a sealed system, the added refrigerant will leak back out again and there is no way to tell how long it will last. We aren’t the pushy salesmen type, so we got our refrigerant jug and scale in order to do what the customer requested.

We added 2.5 pounds of R410A refrigerant to the machine and it was cooling again. This unit was low on airflow so the temperature split between return and supply was higher than it should have been especially since the house was so warm and the ductwork was in the attic. If a heat pump does not have adequate airflow, you can expect premature failures on the machine, higher energy bills, and expensive repairs in the future. It is so important when commissioning an HVAC unit that the installers of the equipment verify there is adequate airflow available for the size of unit you are installing. Obviously, this was not done by the company that installed this machine which is more than likely why this customer has a refrigerant leak in the first place.

If you live inside of our service area in Northeast Tennessee and are in need of a heat pump repair, please feel free to reach out. We care about our customers and offer options that can best fit your needs. We aren’t going to try to upsell you and push equipment replacements. We present the facts about your HVAC unit and allow you to make an informed decision that best fits your budget and needs. Stay safe and best wishes.

Location: Kingsport, TN

Project Image Gallery

Schedule Your HVAC Service in Johnson City, TN Today!

Or Fill Out Our Quick Form!