Efficient Heat Pump Repair in Johnson City, TN for a New Customer

October 12, 2025

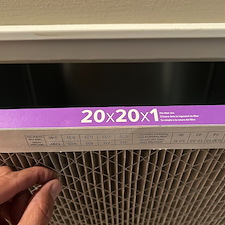

We received a call from a new customer in Johnson City, TN in need of a heat pump repair. Their heat pump for the 2nd floor was not cooling. We advised them to turn the machine off. When we arrived, we went to the 2nd floor thermostat. We confirmed that the indoor blower motor was working by cycling the thermostat in the Fan On position. We had 2 return grilles servicing the 2nd floor unit, but notated that they were using MERV 12 filters which are too restrictive when they are only 1” thick. We let the customer know that they should downgrade their filters to a MERV 4 to 6 or upgrade to a 4” or 5” thick media filter if they want to continue to filter their air at that level. The filters were whistling, were hard to pull away, and slapped close when you let your hand off of them. These symptoms are a sign that the indoor unit is starving for air.

Next, we put the unit into cooling mode and confirmed that the blower motor did turn on. We went outside to the 2nd floor heat pump and noticed that it was not running. We pulled the outdoor disconnect and it was hard to remove. We lubed the disconnect pullout with dielectric grease. We opened the service panel to the heat pump and noticed that the Coresense Diagnostics was locked out on flash code #4 (Locked Rotor). The customer went upstairs and turned the thermostat to off while we continued working.

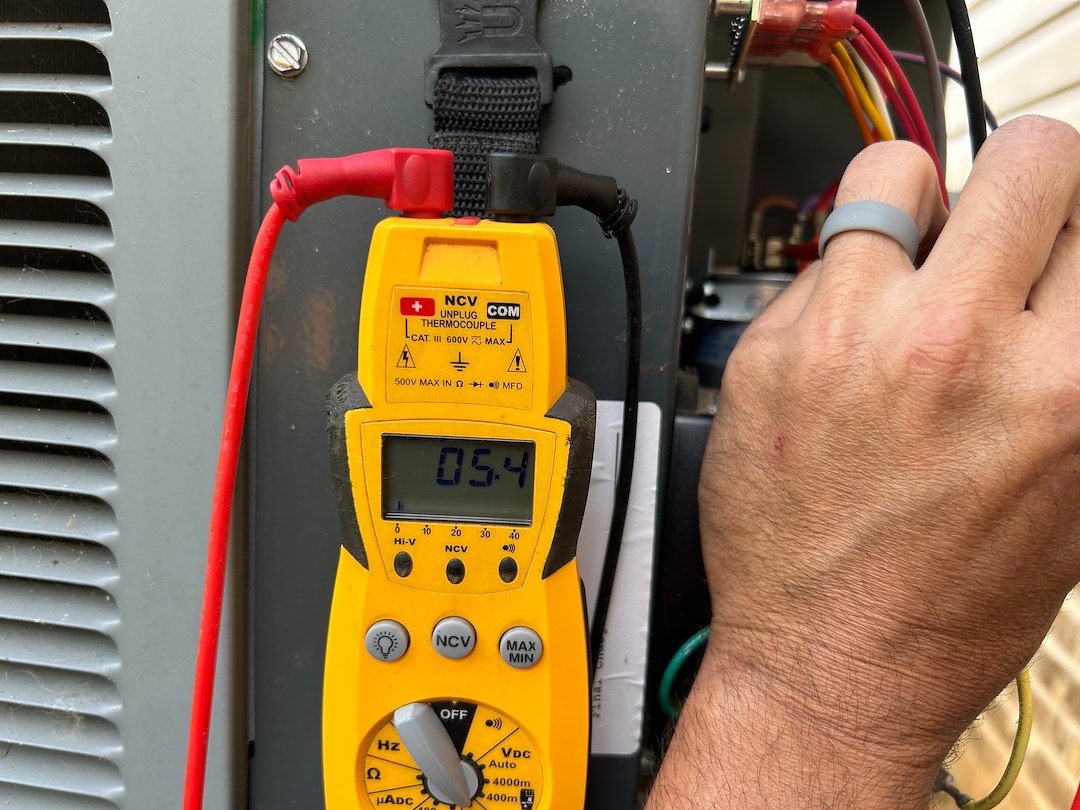

We removed the wires from the dual run capacitor and tested the hermetic side of the capacitor first. We only had 5.4 MFD instead of 35 MFD. The discrepancy in microfarads would definitely cause the machine to draw above the locked rotor amp rating of 72.5 while trying to start. We let the customer know that we found an issue with the heat pump and quoted a price for the repair. The quote was approved and we went to our van to grab the correct sized dual run capacitor.

We installed a new Mars USA made dual run capacitor to replace the failed one. We tightened the stake-ons for the wires to confirm that we would have a nice tight connection for each wire. We cleaned the inside of the service panel because it was full of dead bugs and cob webs. We reset the Coresense Diagnostics and restored high voltage to the outdoor unit. We placed our amp clamp on the compressor common wire to measure an inrush amp reading at startup to confirm that we were pulling below the LRA rating on the unit’s data tag.

We restored a call for cooling at the thermostat and confirmed that the indoor and outdoor unit turned on. We documented our inrush amp reading which was well below the LRA rating on the compressor. We measured amps on the compressor and outdoor fan motor while the unit was running and confirmed that those readings were in range of where they were supposed to be. We offered to hook up probes to the system and the customer declined additional work on the unit since it had been cooling great and then suddenly stopped. We did put temperature probes on the return and supply and confirmed that we were falling within our target range and we reminded the customer to get some new air filters with a lower MERV rating.

If you live within our service area of Northeast Tennessee and are in need of a heat pump repair, please feel free to reach out to us. We would be happy to assist you with your HVAC repair. Best wishes and stay safe.

Location: Johnson City, TN

Project Image Gallery

Products Used

Mars USASchedule Your HVAC Service in Johnson City, TN Today!

Or Fill Out Our Quick Form!