Thorough Heat Pump Repair in Unicoi, TN Got This Customer Operational Again After Rodents Chewed Up His Heat Pump Wiring

October 20, 2025

We received a call from an existing customer in need of a heat pump repair in Unicoi, TN. He stated that nothing was working on his 9-year-old American Standard heat pump. He said that he had a thermostat display, but the blower wasn’t turning on and neither was the outdoor unit. We advised him to turn the thermostat to the off position until we got over there.

When we arrived, we looked at the indoor thermostat and tested for low voltage at the terminal block. We did not have 24 volts at the indoor thermostat which is why nothing was operating. We went under the home into the crawl space and looked at the SS2 auxiliary drain float switch and it was dry, so it wasn’t causing our issue with losing our control low voltage. We opened the indoor unit and had high voltage to the indoor unit at the inline breakers on each side. We had high and low voltage at the step-down transformer as well. We followed our low voltage hot wire and found a blown low voltage fuse on the hot wire which is why nothing on the HVAC unit was operating.

Since we had a blown low voltage fuse on our hot wire, we needed to determine if anything caused it to blow. We turned off the high voltage to the HVAC unit inside and outside and let the customer know that we could have a low voltage short somewhere in the HVAC system. We let him know that we needed to inspect the wiring for shorts to determine if the fuse popped for a reason or if it was just a fluke. Low voltage shorts can be difficult to find sometimes and other times it can be a relatively quick process.

We went back under the house and looked at the low voltage wiring inside the machine and entering the machine to see if we could find anything obvious like a wire rub out. We quickly pulled the inline breaker bracket and tested the coil resistance on the heat kit low voltage relays. All of the coils tested in range. We mounted the bracket back into place. We installed a resettable fuse tool into the low voltage fuse location. We disconnected all of the low voltage control wiring inside the machine and separated them for testing. We restored high voltage to the machine and began going through each circuit with our short pro tool to find out what circuit or circuits were causing the issue. We located numerous shorts on the wiring leading to the outdoor heat pump and no shorts going up to the thermostat.

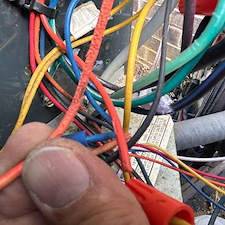

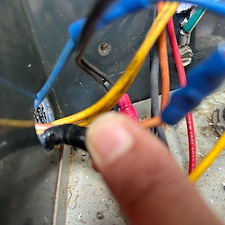

We shut off high voltage to the HVAC system again. We inspected the thermostat wiring leading to the outdoor heat pump and it looked fine. We went to the outdoor heat pump and removed the electrical control panel to the unit and found a massive rodent nest inside the control panel. Luckily, Jimmy the Mouse wasn’t home as we removed his house from inside the control panel and placed it into a trash bag. We inspected the wiring inside the control panel and found multiple wires that had been chewed up or chewed through completely which is what was causing our low voltage shorts to ground. We opened the side panel of the unit and found more wires that were chewed up. We popped the top on the unit and looked at the wiring down inside the machine and it looked like it wasn’t bothered.

We let the customer know what we had found and showed him pictures of the mess created by the rodents. We gave him an estimate on what it would take to fix the wiring up and advised him that we might have some other damages to the system, but we wouldn’t know until we rectified the wiring issues. We gave him an estimate on a worst-case scenario as well. We received approval to proceed with trying to get the unit operational again.

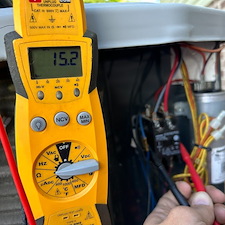

We began with repairing the wiring or replacing the wiring that was chewed up or chewed through by the rodents. We had to correct wiring on the Y circuit to the defrost control board, the outdoor ambient temperature thermistor, the outdoor coil temperature thermistor, the reversing valve solenoid coil, and the control wiring to the outdoor heat pump R, C, Y, O, & W. Once we either replaced or repaired the wiring, we tested the low voltage coil resistance on the high voltage contactor to confirm it wasn’t damaged and it tested perfectly fine. We also noticed some oil residue at the true suction line service port, so we added some Nylog thread sealant on the service port threads where the valve cap goes to prevent any seepage in the future. Since, we were there we tested the dual run capacitor as well and it tested in range as well. We also took an outdoor ambient temperature reading and tested the resistance on the outdoor ambient temperature thermistor and the outdoor coil temperature thermistor. Both thermistors tested in range based on the outdoor ambient temperature, which saved the customer money on having to buy new parts. We inspected other wiring around the outdoor heat pump and couldn’t find anything else that was chewed up at this time. We lubed the outdoor disconnect pullout with di-electric grease and restored high voltage to the outdoor heat pump.

We went back under the house and restored high voltage to the indoor unit as well. We tested the low voltage circuits to the outdoor unit with our short pro tool and did not have any further shorts detected to the outside anymore. We shut down high voltage to the indoor unit again and re-wired the low voltage control wiring inside the machine. We tested continuity on the SS2 float switch and it was intact and confirmed its operation in the low voltage circuit. We removed our resettable low voltage fuse tool from its location and installed a new 5-amp low voltage fuse in its place. Since, we were already under the house we snaked and flushed the drain line to the outside because we noticed it had buildup in it from running over the years. We primed the p-trap upon completion of the drain line flush and restored high voltage to the indoor unit. We placed the panel back onto the machine and decided it was time to test the system out from the thermostat.

We went inside to the thermostat and turned the HVAC system on. We confirmed that both the indoor and outdoor units were working again. We offered to hook up probes to the system in order to monitor the system’s refrigerant charge, but the customer declined the additional check to his system. Instead, we placed temperature probes on the return and supply and confirmed that we were falling into range with where the system should be operating after about 15 minutes of run time. We advised the customer to contact an exterminator in order to prevent rodents from getting back into his outdoor heat pump again. We also advised trimming back the overgrown flower bed next to the unit as well.

If you reside within our service area of Northeast Tennessee and are in need of a heat pump repair, please feel free to contact us. We would be happy to help get your HVAC unit operational again. Stay safe out there and best wishes.

Location: Unicoi, TN

Project Image Gallery

Schedule Your HVAC Service in Johnson City, TN Today!

Or Fill Out Our Quick Form!