Top Quality Heat Pump Repair Restores Comfort in Bluff City, TN

May 16, 2025

Received a call from a new customer in Bluff City, TN in need of a heat pump repair. She stated that her 10-year-old heat pump kept shutting off and wouldn’t cool anymore. She said that if she sucked the water out of the emergency drain pan that it would start working again for a few hours and then quit again. She said that the water was coming out of some tape above where the drain line was located. She said that this unit had been a problem unit since it was installed by the company that put it in.

When we arrived, we took a look at the indoor unit located in the garage. The unit was running because she had just sucked more water out of the emergency drain pan. The condensate from the indoor coil was pouring out of the auxiliary drain hole opening which was covered with black tape. The water was not flowing down the drain line and into the condensate pump as it is intended to do.

We powered the unit off and disconnected the condensate pump from its mounting location and snaked the condensate drain line. We had a tough blockage to penetrate, but once we broke the blockage free the water that was pouring from the auxiliary drain opening started flowing down the drain line. Once the water finished flowing, we put our shop vac on the line and sucked the line for a couple of minutes to confirm we cleared out the debris from the line. Then, we flushed the drain line with a foaming drain cleaner. We followed it up with 2 gallons of enzyme treated water to help flush the line out and to further clean out the discharge line leaving the condensate pump to the outside. The enzyme treated water helps to remove the slime from the drain lines. We popped the top of the condensate pump and vacuumed out any remaining debris and slime from inside the pump and wiped it with a rag. We reinstalled the pump to its mounting location and proceeded with further repairs.

First, we offered a SS2 or CS2 auxiliary drain float switch in the opening so that we could prevent water from ever getting into the emergency drain pan. One float switch is not enough water protection for a HVAC unit and the emergency drain pan is an absolute last resort or fail safe for your unit. You never want water to reach that pan if you can prevent it. The customer was on a tight budget and asked what other options we could offer. With her budget in mind, we plugged the holes with drain plugs that should have been in place from the start if a float switch was not being used in that opening. No idea why this was not done at installation by the company she had been using.

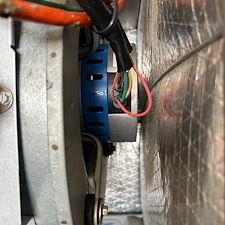

Next, we noticed that the emergency drain pan float switch had a wire that was exposed and not capped off. We added a wire nut to the exposed wire and taped it with Super 33 electrical tape as a redundant back up to the wire nut to help prevent it from coming off in the future. The customer’s p-trap had been sweating because the unit was installed in an unconditioned space and had caused some damage to the concrete. We let her know that the p-trap should be insulated to prevent nuisance sweating during cooling mode operation. The customer had some insulation and box tape on hand and with her budget in mind, we used what she had and insulated the p-trap with the insulation she provided and the tape. Definitely different than what we would have used, but it will do the job and it didn’t cost her any extra money. We also placed a plug in the condensate pump that was open to the garage to help prevent bugs and debris from getting into their condensate pump in the future.

When confirming that the condensate pump was discharging the condensate to the outside of the home, we noticed that her discharge line had rotted and broken off at the foundation of her home because it was never protected from the sun. The exit point of the discharge line was on the South side of her home. We advised using a brass coupling and extending the condensate line away from the foundation of her home. We also always encase our discharge lines inside of a UV resistant flexible black conduit and wrap the conduit with a UV resistant 10 MIL tape to further protect the discharge line from sun damage. The customer wanted to fix the issue, but was on a tight budget. She just couldn’t afford any additional work at this time and was wanting to DIY the job. Being that her foundation was taking such a beating and we understand how tough it has been with this inflation we have been experiencing, we donated enough heavy-duty condensate tubing to her in order to get the discharge line out and away from the foundation of the home. We went to our van and provided her with pictures of the brass coupling, the worm gear clamps, the UV resistant conduit, and the UV resistant tape that she could buy from local stores so that she could cut her costs down on the job to a minimum, yet still protect her home’s foundation from being washed out.

We noticed that the indoor unit had a 14” flexible duct as the only return coming back into the return plenum which would not provide nearly enough airflow for a 3-ton heat pump to operate properly. We let her know that she was lacking return airflow to her machine and that having that big of a discrepancy in airflow would cause premature failures on expensive components inside her machine, a loss of capacity in the system, and an increase in energy usage. We noticed that she had an aftermarket ECM blower motor inside her indoor unit which had been replaced in the past. She said that it had failed a few years ago and it had to be replaced. She also let us know that she already had to replace the heat pump’s compressor as well. These expensive component failures are the types of failures you can expect when you starve a heat pump of the airflow that it needs in order to operate within its design parameters.

We advised her that the return grille inside the home needed enlarged to meet the minimum requirements of her unit size and also that the return duct going into the return plenum needed to be enlarged in order to meet the minimum airflow requirements of her machine. We let her know the risks involved with leaving it the way it was and made sure to document those facts on the receipt as well. We also let her know that her outdoor unit needed to be cleaned due to grass and other debris that was impacted into the coil. We understood that her budget was tight, but did want to mention this so that she was aware.

If you are in need of a heat pump repair and live within our service area of Northeast Tennessee, please feel free to reach out to Magnolia Services based out of Johnson City, TN. We value our customers and try to go the extra mile to provide you with quality workmanship at a reasonable rate. We are not the pushy salesmen dressed in white shirts. A customer that has never been informed of issues with their HVAC is a customer that will have ongoing issues with their equipment. An informed customer can make informed decisions based on the facts. We will present the facts to you in a clear and concise manner and let you make an informed decision on what you do and don’t want to do based on your budget and the facts presented. Stay safe and best wishes.

Project Image Gallery

Schedule Your HVAC Service in Johnson City, TN Today!

Or Fill Out Our Quick Form!